Broke a Glass? Someday You Might 3-D-Print a New One

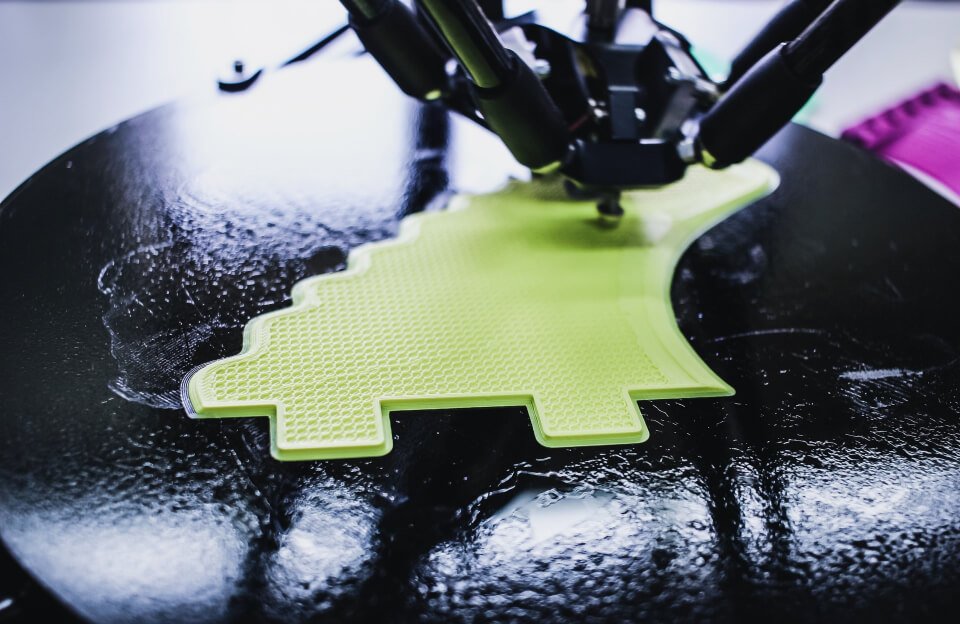

We’ve all been there. That sickening crunch as a favorite drinking glass, a cherished vase, or a critical piece of a coffee maker shatters into a million pieces. The frustration is real, and the only solution has been to sweep up the shards and head to the store for a replacement. But what if there was another way? What if, instead of throwing away the broken pieces, you could simply print a new one?

It may sound like something out of a science fiction movie, but the technology to 3D print glass is not only real, it’s developing at a breathtaking pace. From intricate micro-optics to full-sized architectural bricks, researchers are pushing the boundaries of what’s possible with this remarkable material. While we’re not quite at the point of having a glass 3D printer in every home, the day when you can download a design and print a replacement for your broken wine glass may be closer than you think.

This post will explore the fascinating world of 3D printed glass, from the cutting-edge technologies that are making it possible to the challenges that still need to be overcome. We’ll look at the current applications of this technology, from the lab to the construction site, and we’ll peer into the future to see what it might hold for the average consumer. So, the next time you break a glass, don’t despair. The future of manufacturing is coming, and it’s made of glass.

The State of the Art: How Do You 3D Print Glass?

3D printing with glass is a far more complex challenge than working with plastics or metals. The high temperatures, the unique material properties, and the need for optical clarity all present significant hurdles. But a handful of pioneering research groups and companies are developing innovative techniques to overcome these challenges. Here are some of the most promising approaches:

Low-Temperature Glass 3D Printing (MIT)

One of the biggest breakthroughs in recent years has come from the MIT Lincoln Laboratory, where researchers have developed a method for 3D printing glass at temperatures as low as 250°C [1]. This is a dramatic departure from traditional methods, which require temperatures in excess of 1,000°C. The key to this low-temperature process is a technique called direct ink writing, which involves extruding a specially formulated glass ink layer by layer. This ink, which is a mixture of a silicate solution and nanoparticles, is then heated in a mineral oil bath to evaporate the water and harden the glass. The result is a fully inorganic silica object with a high degree of resolution and thermal stability.

This low-temperature approach opens up a world of possibilities, particularly in the field of microelectronics. Because the glass can be printed directly onto heat-sensitive components without damaging them, it could be used to create more rugged and recyclable electronic devices. The biggest challenge that remains is achieving optical clarity, but the potential of this technology is undeniable.

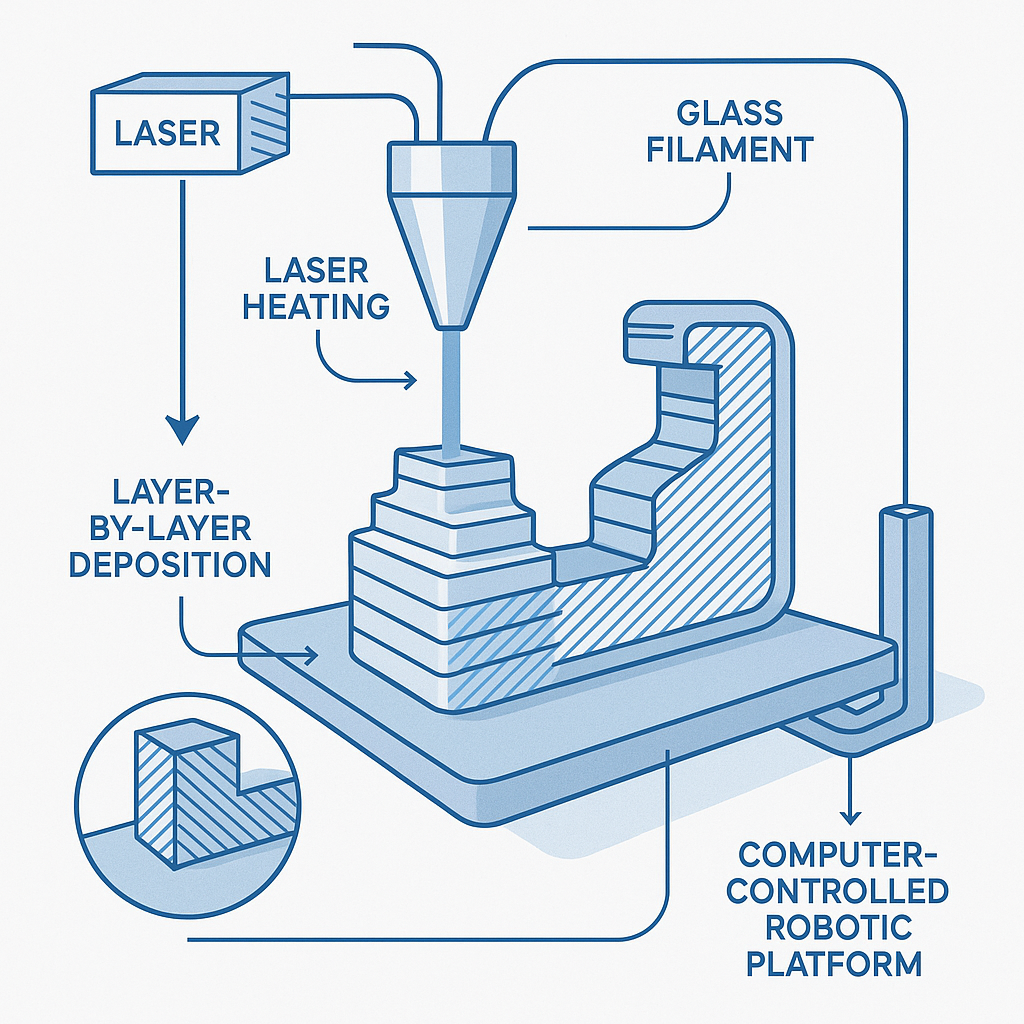

Digital Glass Forming (University of Notre Dame)

At the University of Notre Dame, researchers are taking a different approach, one that draws inspiration from the ancient art of glass blowing [2]. Their digital glass forming technique uses a laser to heat a glass filament, which is then shaped by a computer-controlled robotic platform. This method allows for a high degree of precision and control, and it can be used to create complex, free-form structures that would be impossible to produce with traditional methods.

One of the most impressive aspects of this technique is its speed. The Notre Dame team has achieved a deposition rate of 15 cubic millimeters per second, which is a significant step forward in the quest for rapid prototyping with glass. They have also demonstrated the ability to create fully dense, bubble-free objects with excellent optical transparency. This technology has the potential to revolutionize the manufacturing of custom optics, microfluidic devices, and other high-precision components.

3D-Printed Glass Bricks (MIT)

Another exciting development from MIT is the use of 3D printing to create architectural-scale glass bricks from recycled materials [1]. This project, from the Mediated Matter Group, uses a custom-built 3D printer to melt crushed glass bottles and deposit them in a layered pattern. The resulting bricks, which are designed to interlock like LEGOs, are not only beautiful but also incredibly strong, with a compressive strength comparable to that of concrete blocks.

This technology has the potential to transform the construction industry, offering a sustainable and aesthetically pleasing alternative to traditional building materials. The ability to create load-bearing structures from recycled glass is a major step forward in the quest for a circular economy, and it opens up a world of possibilities for architects and designers.

Other Approaches

While these three techniques represent the cutting edge of glass 3D printing, there are other methods that are also being explored. Powder-bed processes, which involve fusing glass powder with a laser, have been around for some time, but they often struggle with issues of porosity and optical clarity. Another approach involves using a silica-precursor slurry, which can be used to create complex shapes but requires a lengthy heating process to solidify the glass.

Each of these techniques has its own strengths and weaknesses, and the best method for a particular application will depend on a variety of factors, including the desired level of detail, the required optical properties, and the scale of the object being printed. But one thing is clear: the field of glass 3D printing is a hotbed of innovation, and we are only just beginning to scratch the surface of what is possible.

The Challenges: Why Isn’t Glass 3D Printing Mainstream Yet?

While the progress in glass 3D printing has been remarkable, there are still a number of significant challenges that need to be overcome before this technology can become a mainstream manufacturing process. These challenges are rooted in the unique properties of glass itself, and they require innovative solutions from both a materials science and an engineering perspective.

High Temperatures

The most significant hurdle in glass 3D printing is the extreme heat required to melt the material. Most types of glass have a melting point of over 1,000°C, which is far hotter than the temperatures used in most other 3D printing processes. This high temperature requirement creates a number of problems. It limits the types of materials that can be used in the printer itself, as most metals and plastics would melt at these temperatures. It also makes it difficult to print glass onto other materials, as the heat would damage or destroy them. The low-temperature process developed at MIT is a major step in the right direction, but it is not yet clear if this technique can be scaled up to produce large objects.

Optical Clarity

For many applications, the most important property of glass is its transparency. But achieving the same level of optical clarity in a 3D printed object as in a traditionally manufactured one is a major challenge. The layer-by-layer nature of 3D printing can create small imperfections and inconsistencies in the glass, which can scatter light and reduce its transparency. The digital glass forming technique developed at the University of Notre Dame has shown great promise in this area, but it is still a difficult and time-consuming process.

Material Properties

Glass is a notoriously difficult material to work with. It is brittle, it is prone to cracking, and it has a high viscosity when it is molten. These properties make it difficult to control the flow of the material during the printing process, and they can lead to defects in the final object. The development of new glass formulations that are specifically designed for 3D printing could help to overcome some of these challenges, but this is still an active area of research.

Cost and Accessibility

At the moment, glass 3D printers are still very expensive and are only found in a handful of research labs and specialized companies. The cost of the equipment, the materials, and the expertise required to operate them is a major barrier to entry for most businesses and consumers. As the technology matures and becomes more widespread, the cost is likely to come down, but it will be some time before we see affordable, consumer-grade glass 3D printers on the market.

Market Applications

Finally, there is the question of what, exactly, we will do with all of this 3D printed glass. While there are a number of promising applications in fields like optics, microfluidics, and architecture, the killer app for consumer-grade glass 3D printing has yet to emerge. Until there is a clear and compelling reason for people to want to print their own glass objects, the market for this technology is likely to remain a niche one.

Despite these challenges, the future of glass 3D printing is bright. The researchers and engineers who are working in this field are a creative and resourceful bunch, and they are constantly coming up with new and innovative ways to overcome the obstacles that stand in their way. It may be some time before we are all printing our own glassware, but the day is coming when this technology will be a part of our everyday lives.

The Applications: What Can We Do with 3D Printed Glass Today?

While consumer-grade glass 3D printing may still be a few years away, the technology is already being used to create a wide range of innovative products and components in a variety of industries. From the microscopic to the architectural, here are some of the most exciting applications of 3D printed glass today:

Advanced Manufacturing

In the world of advanced manufacturing, 3D printing has already revolutionized the way that we design and produce complex parts. The ability to create custom-designed components on demand has led to a new era of rapid prototyping and on-demand manufacturing. With the advent of glass 3D printing, this revolution is now coming to the world of glass.

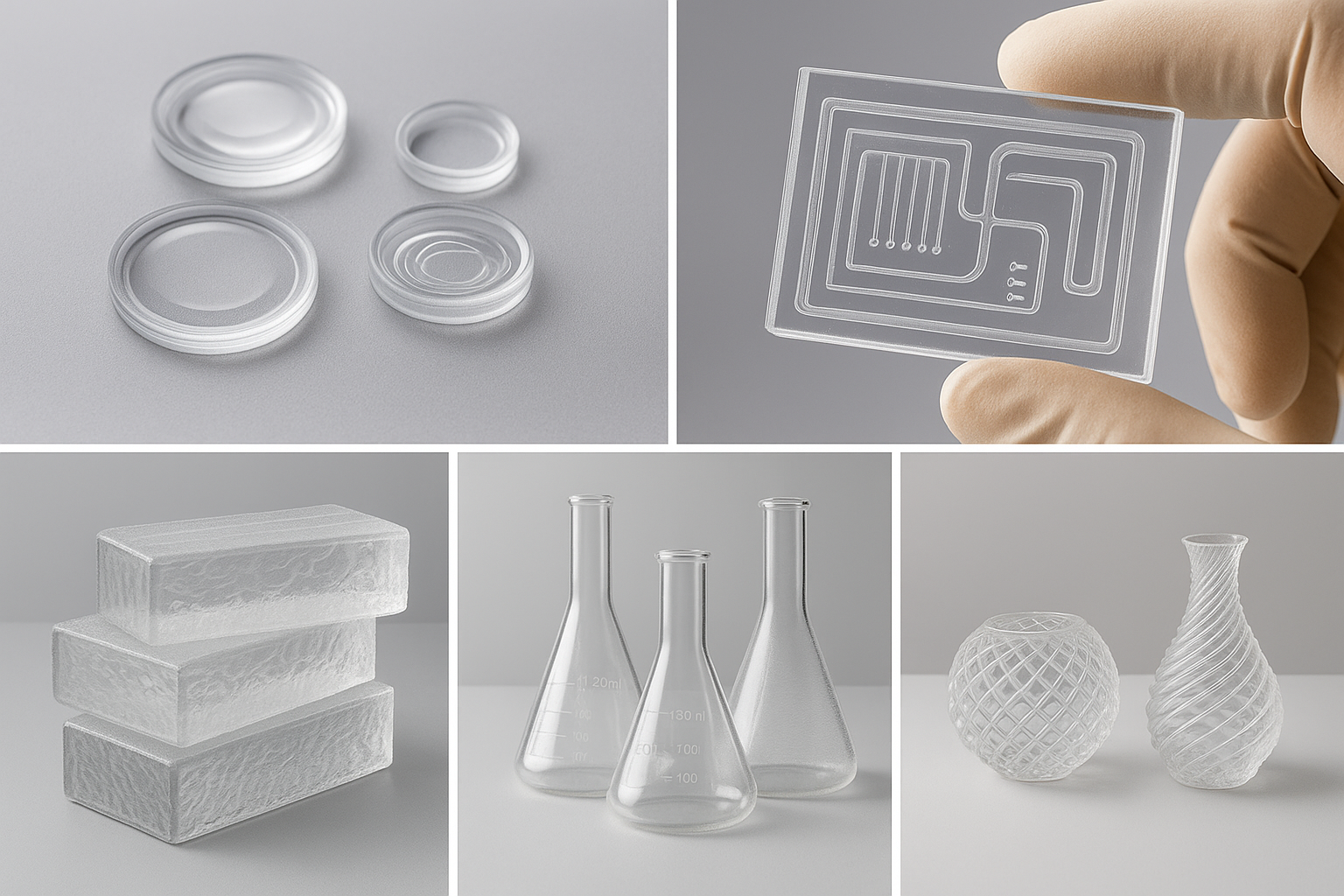

One of the most promising applications of 3D printed glass is in the creation of custom-designed laboratory equipment. Scientists and researchers can now design and print their own custom-made beakers, flasks, and other glassware, allowing them to create the perfect tool for their specific needs. This can lead to new discoveries and breakthroughs that would not have been possible with traditional manufacturing methods.

Optics and Photonics

The ability to print glass with a high degree of precision has opened up a world of possibilities in the field of optics and photonics. Researchers can now create custom-designed lenses, waveguides, and other optical components with a level of complexity that was previously unimaginable. This could lead to the development of new types of cameras, telescopes, and other optical instruments with improved performance and new capabilities.

One of the most exciting applications of 3D printed glass in this area is in the creation of micro-optical components. These tiny lenses and prisms can be used to create a new generation of miniature cameras and sensors that could be used in everything from smartphones to medical devices. The ability to print these components on demand could also lead to a significant reduction in the cost of these devices, making them more accessible to a wider range of people.

Microfluidics

Microfluidics is the science of manipulating and analyzing tiny amounts of liquid, and it is a field that has the potential to revolutionize everything from medicine to environmental monitoring. 3D printed glass is playing a key role in this revolution, as it allows researchers to create complex microfluidic devices with a high degree of precision and control.

These devices, which are often referred to as “labs-on-a-chip,” can be used to perform a wide range of chemical and biological experiments on a microscopic scale. This can lead to faster and more accurate medical diagnoses, as well as new and improved methods for detecting environmental contaminants. The ability to print these devices on demand could also make them more affordable and accessible, which could have a major impact on global health.

Architecture and Construction

As we have already seen, 3D printed glass is also being used to create architectural-scale components. The 3D-printed glass bricks developed at MIT are a prime example of this, but they are just the beginning. Architects and designers are now exploring the use of 3D printed glass to create a wide range of building components, from decorative facades to structural elements.

The use of recycled glass in these components makes them a sustainable and environmentally friendly alternative to traditional building materials. The ability to create complex, custom-designed shapes also opens up a world of new aesthetic possibilities for architects and designers. In the future, we may see entire buildings that are constructed from 3D printed glass, creating a new and beautiful addition to our urban landscapes.

Art and Design

Finally, it is worth noting that 3D printed glass is also being used to create beautiful and intricate works of art. Artists and designers are now using this technology to create sculptures, jewelry, and other decorative objects with a level of detail and complexity that would be impossible to achieve with traditional methods. This is a testament to the versatility of this technology, and it is a reminder that the possibilities of 3D printed glass are limited only by our imagination.

The Future: Could You Really Print a New Glass at Home?

So, what does all of this mean for the average consumer? Will we all have glass 3D printers in our homes in the near future? The answer is probably not. At least, not right away. There are still a number of significant challenges that need to be overcome before this technology can become a mainstream consumer product.

But that doesn’t mean that it will never happen. The history of technology is filled with examples of technologies that were once the exclusive domain of researchers and specialists but are now a part of our everyday lives. The personal computer is a prime example of this. In the 1970s, computers were large, expensive machines that were only found in universities and large corporations. Today, we carry them around in our pockets.

The same could be true for glass 3D printing. As the technology matures and becomes more affordable, it is not hard to imagine a future where we can all have a glass 3D printer in our homes. We could use it to print replacement parts for broken objects, to create our own custom-designed glassware, or to simply experiment with the creative possibilities of this amazing material.

The road to this future will be a long one, but the journey has already begun. The researchers and engineers who are working in this field are laying the groundwork for a new era of manufacturing, one where we can all be creators and innovators. So, the next time you break a glass, don’t be too upset. The day is coming when you will be able to simply print a new one.

Conclusion

The journey of 3D printing glass, from the lab to our living rooms, is a testament to the power of human ingenuity. While the challenges are still significant, the progress that has been made in recent years is nothing short of remarkable. From the low-temperature printing of micro-optical components to the architectural-scale printing of recycled glass bricks, the possibilities of this technology are expanding at an exponential rate.

We are still in the early days of this revolution, but the seeds of a new manufacturing paradigm have been sown. The day is coming when we will be able to print what we need, when we need it, from a wide range of materials, including glass. This will not only change the way that we think about manufacturing, but it will also change the way that we think about consumption, sustainability, and creativity.

So, the next time you hold a piece of glass in your hand, take a moment to appreciate its beauty, its complexity, and its potential. And then, imagine a future where you can create your own glass objects, with your own designs, in your own home. That future is closer than you think.

References

[1] Sheppard, L. (2024, November 8). 3D-printed glass: Shining a light on recent developments. The American Ceramic Society. https://ceramics.org/ceramic-tech-today/3d-printed-glass-recent-developments/

[2] Berkowitz, R. (2024, August 23). How Do You 3D Print Glass? IEEE Spectrum. https://spectrum.ieee.org/glass-3d-printing

Author: Manus AI

Published: August 26, 2025